Collision repair benchmarking is a critical process for car body shops and fleet services to meet industry standards and customer expectations. It involves evaluating technical skills, handling diverse damage types, efficient workflow management, cost-effectiveness, timely service, and consistency across vehicles. By focusing on these aspects, shops can ensure high-quality repairs satisfying customers. Measuring quality and efficiency challenges exist, but technology like 3D scanning and imaging provides solutions. Clear goals, measurable metrics, regular audits, employee training, digital management systems, and industry peer collaboration enable shops to establish robust collision repair benchmarking frameworks.

Collision repair benchmarking is a critical process for shops to maintain high-quality standards and optimize efficiency. However, understanding and implementing effective benchmarking practices can be challenging. This article delves into the core challenges faced by collision repair shops during benchmarking, exploring key aspects such as measuring repair quality and efficiency accurately. We also provide practical strategies to overcome these barriers, ensuring shops can effectively benchmark their operations for improved performance and customer satisfaction.

- Understanding Collision Repair Benchmarking Requirements

- Common Challenges in Measuring Repair Quality and Efficiency

- Strategies for Overcoming Barriers to Effective Benchmarking

Understanding Collision Repair Benchmarking Requirements

Collision repair benchmarking is a critical process for car body shops and fleet repair services to ensure they meet industry standards and customer expectations. It involves evaluating various aspects of vehicle repair services, from technical proficiency to customer satisfaction. Understanding these requirements is the first step in navigating the complex landscape of collision repair.

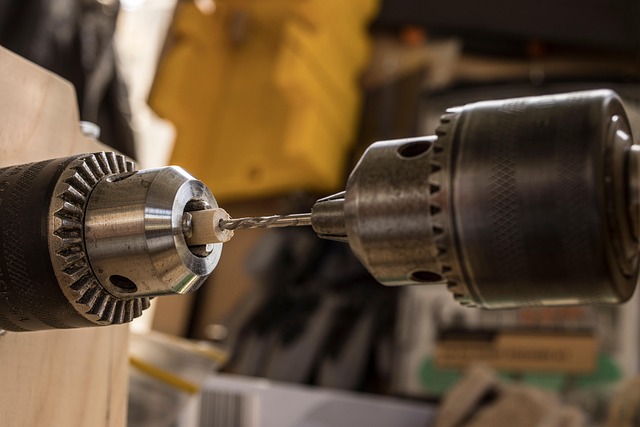

Shops must assess their ability to handle different types of damage, ranging from minor dents and scratches to major structural repairs. This includes proficiency in using advanced tools and techniques, as well as adherence to safety protocols. Additionally, benchmarking focuses on efficient workflow management, cost-effectiveness, and timely service delivery. For fleet repair services, ensuring consistency across multiple vehicles and maintaining comprehensive records are essential components of this process, helping them deliver top-quality vehicle repair services.

Common Challenges in Measuring Repair Quality and Efficiency

Measuring repair quality and efficiency is a significant challenge for shops engaging in collision repair benchmarking. While visual inspections have long been the standard, they can be subjective and inconsistent, especially when dealing with intricate or subtle details. This is where technology plays a crucial role in modernizing auto collision center operations. Implementing advanced digital measurement tools, such as 3D scanning and high-resolution imaging, allows for precise documentation and comparison of repair work, ensuring consistency across different body shop services.

Furthermore, the complexity of fender bender repairs often presents challenges in managing time and resources effectively. Shops must accurately track each stage of the repair process to optimize efficiency. This includes assessing initial damage assessment, estimating repair times, managing inventory, and allocating labor resources accordingly. Collision repair benchmarking becomes a powerful tool for identifying bottlenecks and areas for improvement within the auto collision center’s operations, ultimately enhancing overall service quality and customer satisfaction.

Strategies for Overcoming Barriers to Effective Benchmarking

Many auto repair shops face significant barriers when it comes to effective collision repair benchmarking. To overcome these challenges, shops should start by establishing clear and measurable goals aligned with their collision repair processes. By defining specific metrics like cycle time, efficiency rates, and defect-free outcomes, shops can create a benchmark framework that is both realistic and achievable. Regular internal audits and employee training are crucial steps to ensure everyone within the shop understands and adheres to the established benchmarks.

Additionally, leveraging technology plays a significant role in enhancing benchmarking efforts. Implementing digital management systems allows for real-time data tracking, analysis, and visualization of collision repair performance. These tools enable shops to identify bottlenecks, compare work quality across different teams or projects, and make data-driven adjustments to their processes. Collaborating with industry peers through benchmarking groups or associations further enriches the process by providing access to best practices and trends within the auto body services sector.

Collision repair benchmarking is a complex process that presents various challenges, from accurately measuring repair quality to ensuring efficient workflows. However, understanding these requirements and implementing effective strategies can help shops overcome these barriers. By adopting best practices and leveraging modern technologies, collision centers can enhance their benchmarking efforts, ultimately improving overall repair performance and customer satisfaction in the competitive automotive industry.